Motor is everywhere in the field of equipment. This is not a lonely equipment, reliable pumps need reliable motors, the quality of the motor directly affects the normal operation of the equipment. Motor type, soft start mode, selection steps, motor enterprises worthy of attention......These are all important issues that determine the working state of the motor. Now let's take a look at the knowledge about the motor.

Basic knowledge of motor 1: the difference between all kinds of motors

1The difference between DC and AC motors

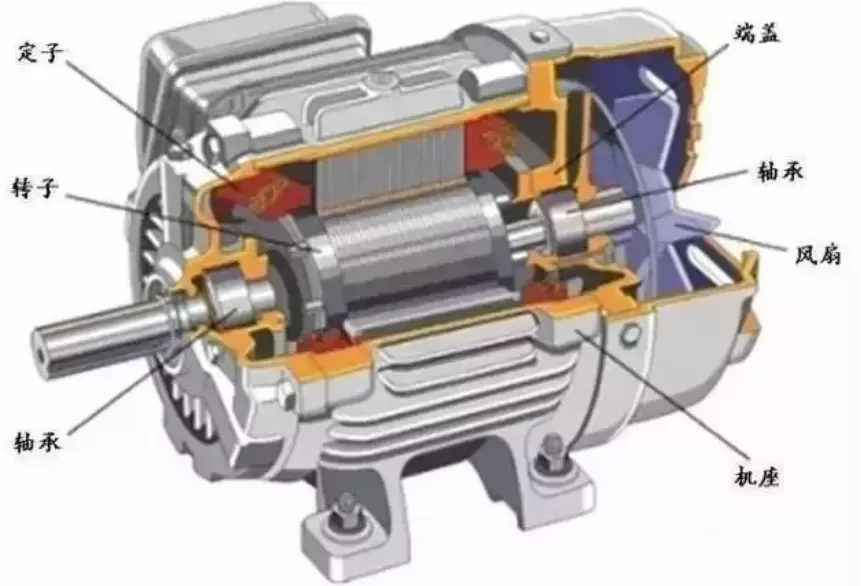

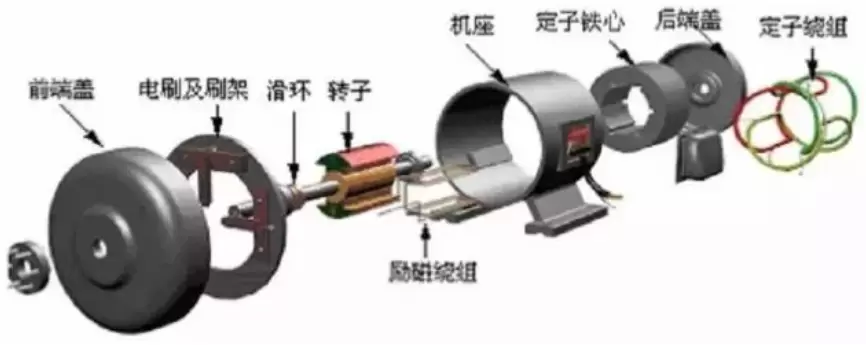

As the name implies, DC motors use DC as power supply, while AC motors use AC as power supply. In terms of structure, the principle of DC motor is relatively simple, but its structure is complex and it is not easy to maintain. The principle of AC motor is complex, but its structure is relatively simple, and it is easier to maintain than DC motor.

(schematic diagram of DC motor structure)

(schematic diagram of AC motor structure)

In terms of price, the DC motor with the same power is higher than the AC motor. Including the speed control device, the price of DC is higher than that of AC, of course, there are great differences in structure and maintenance.

In terms of performance, DC motor has stable speed and accurate speed control, which can not be achieved by AC motor, so DC motor has to be used instead of AC motor under the strict requirement of speed. The speed regulation of AC motor is relatively complex, but it is widely used because AC power is used in chemical plants.

2. The difference between synchronous and asynchronous motors

The rotor rotates at the same speed as the stator, which is called synchronous motor. If it is inconsistent, it is called an asynchronous motor.

3The difference between ordinary and variable frequency motors

First of all, it is clear that ordinary motors can not be used as variable frequency motors. The ordinary motor is designed according to constant frequency and constant voltage, so it can not fully meet the requirements of frequency converter speed regulation, so it can not be used as frequency conversion motor. The influence of frequency converter on the motor mainly lies in the efficiency and temperature rise of the motor.

The frequency converter can produce different degrees of harmonic voltage and current in operation, which makes the motor run under non-sinusoidal voltage and current. The high-order harmonics in the converter will increase the stator copper consumption, rotor copper consumption, iron consumption and additional loss of the motor. Among them, the most significant is the rotor copper consumption, which will make the motor extra heating, lower efficiency and output power, and the temperature rise of the ordinary motor will generally increase.10%~20%.

The carrier frequency of the frequency converter ranges from several thousand hertz to ten thousand hertz, which makes the stator winding of the motor bear a high voltage rise rate, which is equivalent to applying a steep impulse voltage to the motor, which makes the turn-to-turn insulation of the motor withstand a serious test.

When the ordinary motor is supplied by frequency converter, the vibration and noise caused by electromagnetic, mechanical, ventilation and other factors will become more complex. On the other hand, the harmonics contained in the frequency conversion power supply interfere with the inherent space harmonics of the electromagnetic part of the motor to form a variety of electromagnetic exciting forces, thus increasing the noise.

Because of the wide range of working frequency and the wide range of rotational speed of the motor, the frequencies of various electromagnetic waves are difficult to avoid the natural vibration frequencies of the structure of the motor.

When the frequency of the power supply is low, the loss caused by the high-order harmonics in the power supply is larger; secondly, when the rotational speed of the flexible motor decreases, the cooling air volume is proportional to the cubic power of the rotational speed, so that the heat of the motor does not radiate and the temperature rise increases sharply. It is difficult to achieve constant torque output.

Basic knowledge of motor II: selection of motor

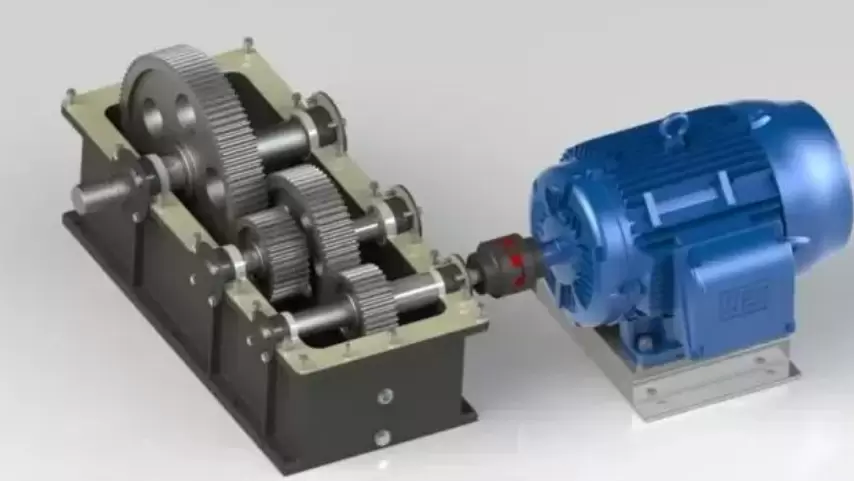

The basic contents of motor selection are: driven load type, rated power, rated voltage, rated speed, other conditions.

Load type:

· DC motor

· Asynchronous motor

· Synchronous motor

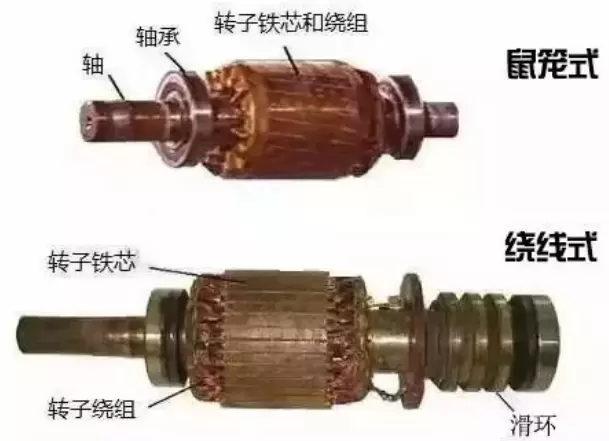

For continuous production machinery with stable load and no special requirements for starting and braking, it is advisable to give priority to ordinary squirrel cage asynchronous motors, which are widely used in machinery, water pumps, fans and so on.

The winding asynchronous motor should be used in the production machinery which requires large starting and braking torque, such as bridge crane, mine hoist, air compressor, irreversible rolling mill and so on.

Synchronous motors, such as medium and large capacity water pumps, air compressors, hoists, mills, etc., should be used in situations where there is no requirement for speed regulation, constant rotational speed or improved power factor.

The speed regulation range is required in 1:3 For the production machinery which needs continuous, stable and smooth speed regulation, it is appropriate to use other excitation DC motor or squirrel cage asynchronous motor or synchronous motor with frequency conversion speed regulation, such as large precision machine tool, gantry planer, steel rolling machine, hoist and so on.

Production machines with large starting distance and soft mechanical characteristics are required to use series or compound DC motors, such as trams, electric locomotives, heavy cranes and so on.

Generally speaking, the motor can be roughly determined by providing the type of load driven, rated power, rated voltage and rated speed. However, if we want to meet the load requirements optimally, these basic parameters are far from enough. Parameters also need to be provided include: frequency, working system, overload requirements, insulation level, protection level, moment of inertia, load resistance moment curve, installation mode, ambient temperature, altitude, outdoor requirements, etc.

Motor basic knowledge 3: ten motor enterprises worth paying attention to

MitsubishiMitsubishi

Founded in 1921 In Japan, as a technology-oriented enterprise, Mitsubishi Electric has deep attainments in compressor, automation, frequency conversion control, power equipment and other high-tech fields, even in Japan.HTV Both spacecraft and Shinkansen favor Mitsubishi Electric's technology. Mitsubishi specializes in advanced technology and expertise in research and development activities, committed to the global power equipment, communications equipment industry automation, electronic components, home appliances and other markets to provide a variety of high-quality products and services.

YaskawaYaskawa

Yaskawa was founded in 1915 Japan, the concept of "mechatronics" advocate, specializing in frequency converters, servo motors, controllers, robots, all kinds of system engineering equipment, accessories and other mechatronics products research and development, production, sales and service of large multinational enterprises. In 1999 Entered the Chinese market in 2000 and opened in Guangzhou, Beijing, Chengdu and other places 8 Home branch.

PanasonicPanasonic

Start with 1918 It is a comprehensive electronic technology enterprise group specializing in the production and sales of various electrical appliances in many fields, such as home appliances, digital audio-visual electronics, office products, aviation and many other fields, under the control of Panasonic Industrial Co., Ltd.1978 After 40 years of development, after 40 years of development, Chinese mainland has initially provided TV sets, refrigerators and other household appliances to the Chinese market, and production equipment and technology to Chinese enterprises. career activities have involved research and development, manufacturing, sales, service, logistics and other aspects.

ABB

A global technology leader, integrating R & D, manufacturing, sales and engineering services for motors, generators, power converters, inverters and transmitters, providing electrical, robotic, automation, motion control products and solutions.ABB Own 130 With years of history, our business has spread all over the world.100 Multiple countries and regions;In China,ABB Has more than 20 local enterprises, online and offline channels covering the country about 700 A city.

SIEMENSSiemens

Siemens began with 1847 In Germany, it has business all over the world.200 Many countries are the world's leading technology companies specializing in electrification, automation and digitization. With excellent professional skills and experience, we are committed to providing professional, efficient energy and resource-saving technologies for the sustainable development of the world and China.1985 Siemens became the first foreign company to carry out in-depth cooperation with China.

Lenze Lentz motor

Germany Lenze From 1947 Since its inception in #, drive and automation systems have been Lenze The core competitiveness also makes Lenze Become one of the most innovative companies in the industry.Lenze The group can also provide customers with a complete product system at all stages of mechanical development, and is one of the few such suppliers in the market.

Schorch Xiao Chi

The company was founded in 1882 It is one of the world's famous motor manufacturers. Because of its high quality of technological innovation, its product quality is outstanding.SCHORCH The motor was once used by the international motor manufacturing giant AEG Group acquisition AEG Many high-power special motors are produced by SCHORCH It is produced by the factory with a label. It can be seen in many influential major projects around the world.SCHORCH The figure of the motor, including many developed countries, is specified in the selection of high-power motors.SCHORCH Brand.

RoshX Ronks.

Germany RoshX Founded in 1921 Focusing on providing high-quality product technology and solutions to a large number of mid-and high-end equipment manufacturers around the world, we are an expert in product development, production, sales and service in the field of industrial automation around the world. As a medium-sized enterprise that has experienced four generations of the family RoshX Up to now, it has become a global and diversified multinational enterprise group, and it is an important partner and backbone of more and more enterprises in the manufacturing field on the road of innovation.

GEGeneral Electric Company of USA

The history of General Electric can be traced back to Thomas·Edison, he 1878 Founded Edison Electric Lamp Co., Ltd.1892 Edison Electric and Thomson-Houston Electric merged to form General Electric, and now GE All over the world 100 Operating in many countries, it is the largest diversified service company in the world, from aircraft engines and power generation equipment to financial services, from medical imaging to television plastics, committed to creating a better life through a wide range of technologies and services.

FascoFasco, USA

The company is close to 100 It has a relatively complete production line of various horsepower motors, fans and gear motors in the world. The main products are:FASCO Motor,FASCO Fan,FASCO Gear motor,FASCO Pump. The company's products are widely used in heating systems, air-conditioning systems, cars,Water pumps and other equipment.

Service

Service